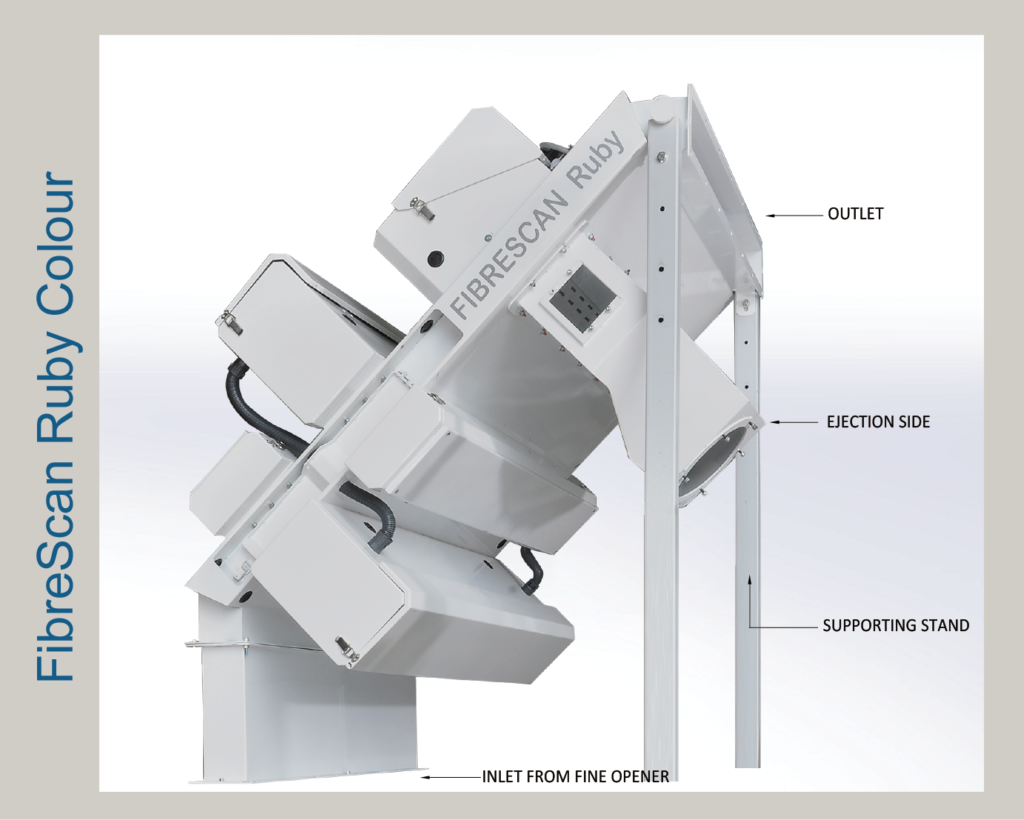

FIBRESCAN RUBY COLOUR

Fibrescan is a simple and reliable system for removal of colour PP contaminants in cotton Blowroom lines.

Multiple miniature camera array sensors interlaced with advanced technology are at the core of FibreScan.

- DIPT (Digital Image Processing Technology)

- PMAC (Pixel Mapping Across Camera sensors )

DIPT, PMAC in combination enhance the effectiveness

of the equipment and provide the best efficiency among this

technology machines in the world.

of the equipment and provide the best efficiency among this

technology machines in the world.

Features

- Better visibility.

- Closer the distance from the opening unit ,small cotton tufts,evenly spread and ensure no

contamination can be hide behind the cotton.

- Closer the distance from the opening unit ,small cotton tufts,evenly spread and ensure no

- Improvement in uv lighting

Camera detection in alternate position

- Improvement in uv lighting

- Minimum space requirement

Designed in the way without inlet and outlet delivery ducts

- Compact machine

Low maintenance and user friendly operating with highest efficiency

- Minimum space requirement

Technical Specifications

| Description | FibreScan Sapphire | |||

| Sensing Technology |

| |||

| Processing | Embedded Controller with DIPT – Digital Image Processing Technology PMAC – Pixel Mapping Across Camera Sensor Array | |||

| Type and No of Cameras | Multiple Camera Array Sensors – 32 Nos MonoChrome Daylight Camera Array Sensor | |||

| Resolution | 2048 * 1 with 128 Pixels for Each Camera | |||

| Camera Scanning Speed (LPS) | upto 12000 LPS for Camera Sensor Array | |||

| Production Capacity | 800 Kgs /Hour | |||

| Throughput Duct size | 1040 * 100 mm | |||

| Size of Machine | 1250 x 500 mm Height will vary depends upon the blowroom layout | |||

| No of Ejection Value | 26 Nos | |||

| Ejection Waste % | Below 0.3 % – 0.5 % Maximum 30 Ejection / Min | |||

| Sensitivity setting | On Area, Vertical, Horizontal Sizes & Size Wise Color selection Settings | |||

| Diagnostics | Camera Sensor, Ejection Valve, Lighting Hours, Intensity and – colour Performance graphs | |||

| Display Features | Comprehensive for Camera Array Sensor | |||

| Tube Light Nos and Wattage | 8 Nos (4*2 – 54 Watts) fluorescent day light | |||

| Control System | Dedicated Embedded controller | |||

| Operator Interface | HMI and Console on Mc | |||

| Power consumption | 1 Kw + Fan | |||

| Power | 415 Volts 3 Phase 50 Hz | |||

| Ejected material Collection | AEMCH – Applied Ejected Material Collection Hanger – Optional | |||

| Booster Fan for Ejected Material | Booster Fan based on Feed Machine Specs | |||

| Ejected Cotton Grams/ Ejection | 0.5 Grams / Ejection after Fine Cleaner 0.9 Grams / Ejection after coarse Cleaner | |||

| Booster Fan for Ejected Material | Booster Fan based on Feed Mc Specs | |||

| Compressed Air Requirements | 3 CFM based on 40 Ejection/Min @ 6.5 Bar | |||