FibreScan Aquamarine CL

TriLinear RGB - Color

Fibrescan is a simple and reliable system for removal of Color PP contaminants in cotton Blowroom lines. Hybrid Intelligent TriLinear RGB Cameras interlaced with advanced technology are at the core of FibreScan.

- DIPT (Digital Image Processing Technology)

- PMAC (Pixel Mapping Across Camera)

DIPT, PMAC in combination enhance the effectiveness of the equipment and provide the best efficiency among this technology machines in the world

Features

- Hybrid Intelligent TriLinear RGB Cameras for every 240 mm of duct

- DIPT – Digital Image Processing Technology for optimum detection of Contaminants.

- Very low clean cotton ejections typically 5% for 40 Ejections/Min.

- Hybrid Embedded Controller enhances

- Easy to clean and Maintain, No PC

- Higher efficiency than other technology

Features

- Hybrid Intelligent TriLinear RGB Cameras for every 240 mm of duct

- DIPT – Digital Image Processing Technology for optimum detection of Contaminants.

- Very low clean cotton ejections typically 5% for 40 Ejections/Min.

- Hybrid Embedded Controller enhances

- Easy to clean and Maintain, No PC

- Higher efficiency than other technology

Technical Specifications

| Description | FibreScan Aquamarine | |||

| Sensing Technology | Quad Tech with TriLinear RGB Line Scan Camera | |||

| Processing |

Real – Time Image Processing Technology DIPT – Digital Image Processing Technology PMAC – Pixel Mapping Across Camera |

|||

| Type and No of Cameras | TriLinear RGB Line Scan Camera 8 Nos | |||

| Resolution | 8192 Pixels (4*2048) for TriLinear RGB camera | |||

| Camera scanning speed (LPS) | Upto 12000 LPS | |||

| Production Capacity | Upto 1000 Kgs /Hour | |||

| Throughput Duct size | 960*100mm | |||

| Size of Machine | 600mm (L) x 1250mm (W) x 2250mm (H) | |||

| No of Ejection Value | 48 Nos | |||

| Ejection Waste % | 0.5 % – 1.0 % for Maximum 50 Ejection / Min | |||

| Sensitivity setting | On Area, Vertical, Horizontal Sizes & Size Wise Settings, Primary Colours | |||

| Diagnostics | RGB Camera, Ejection Valve, Lighting Hours, Intensity graphs | |||

| Display Features | Comprehensive for RGB Camera | |||

| Tube Light Nos and Wattage | 4 Nos(2*2 – 54w Watts) Daylight | |||

| Control System | Dedicated Embedded controller for RGB Camera | |||

| Operator Interface | HMI and Console on Mc | |||

| Power consumption | 1 Kw + Fan | |||

| Power | 415 Volts 3 Phase 50 Hz | |||

| Ejected material Collection | AEMCH – Applied Ejected Material Collection Hanger – Optional | |||

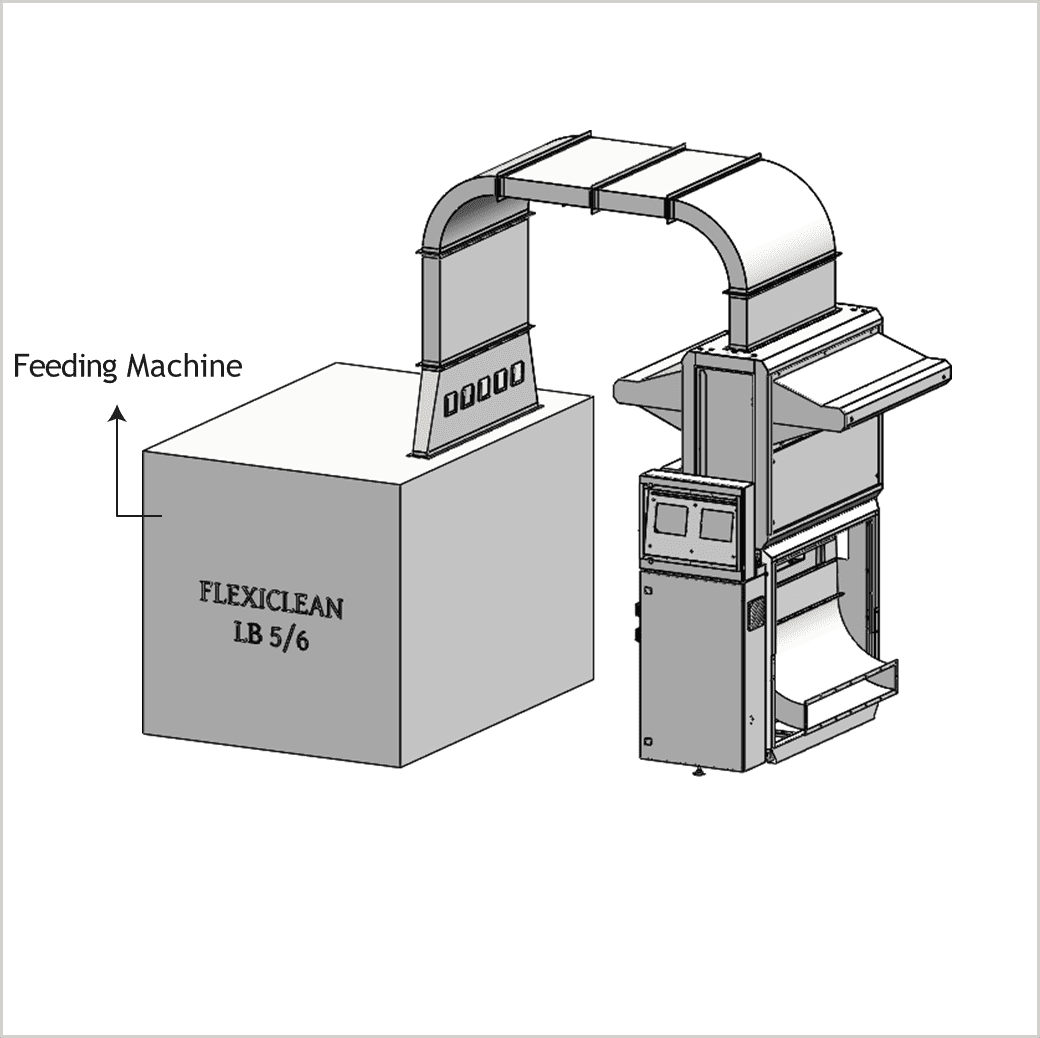

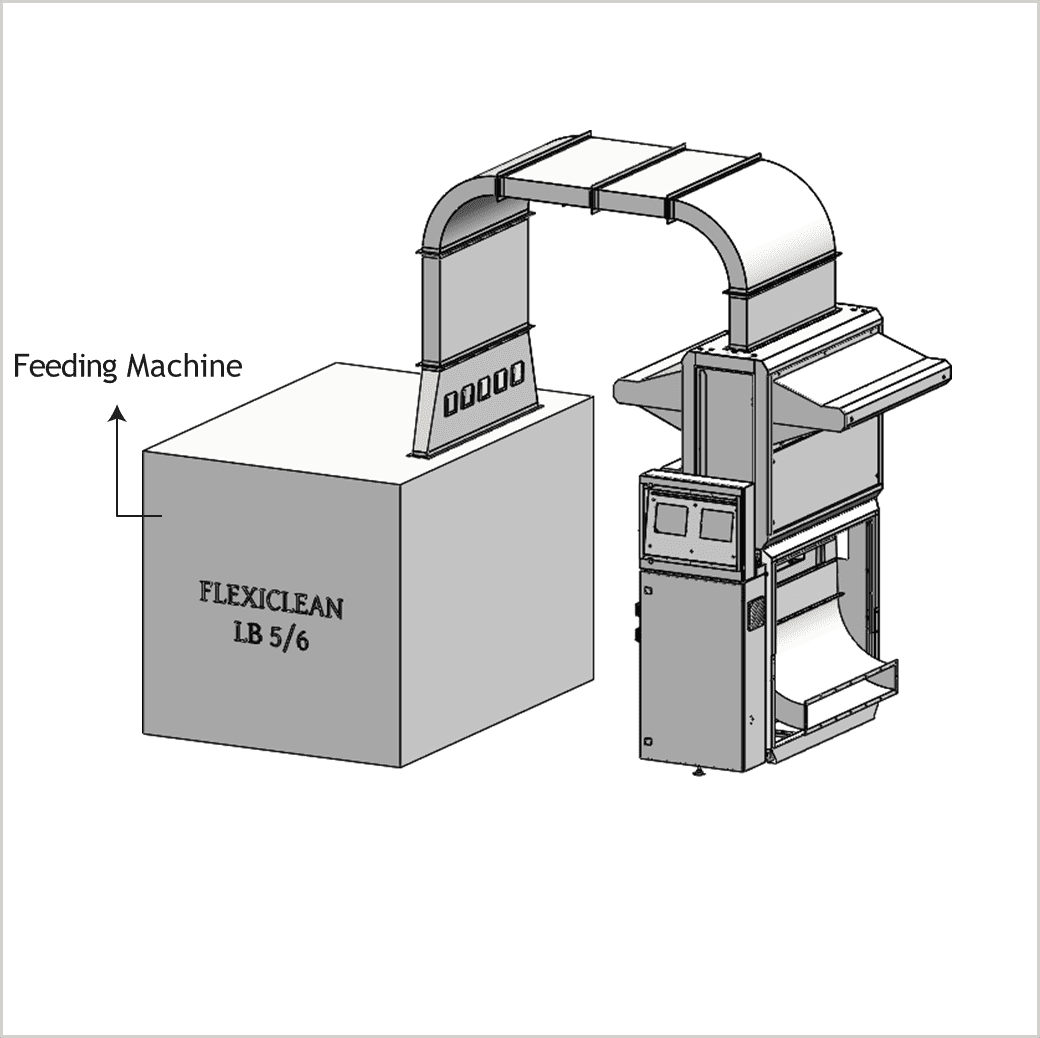

| Booster Fan for Ejected Material | Booster Fan based on Feed Machine Specs | |||

| Ejected Cotton Grams / Ejection | Around 0.7 Grams / Ejection after Fine Cleaner | |||

| Compressed Air Requirements | Below 2 CFM based on 50 Ejection/Min @ 6.5 Bar | |||