Cascade CasLNX 1500

Cascade is a product of Applied since 1980.

Since then it has established itself as a de-facto standard for wrapping procedure in spinning mills.

It is implemented in over 750 mills today.

Cascade is a comprehensive wrapping procedure for spinning mills from Applied. Cascade goes beyond mere statistical computations to provide a complete system for wrapping analysis. Cascade offers comprehensive wrapping rates from Blowroom to Winding.

Cascade can be easily operated on its user friendly system interface and auto start – return of Lea strength tester.

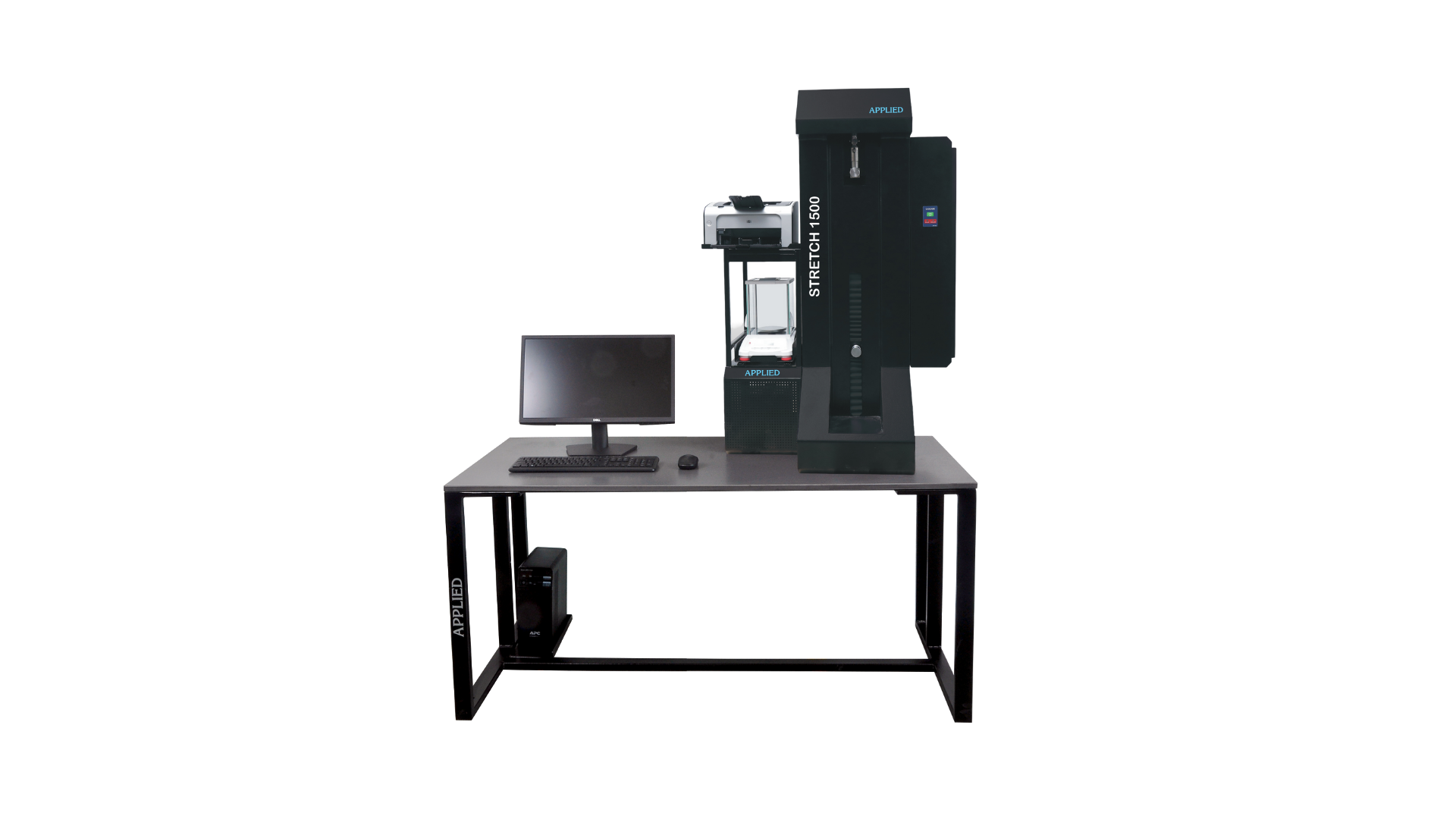

Stretch 1500

Compact Table Top Electronic Lea Tester

Cascade

CasLNX software for wrapping

- Compact Table Top Model – Small Footprint

- Electrically Operated

- Auto return after Lea breakage

- Computerised operator interface for ease of use

- Perfectly Compatible with Cascade System

- Higher Accuracy

- Sleek Model

- Cascade – CasLNX software ubuntu OS

- Interface to our balances through Ethernet

- Interface to stretch 1500 / Ethernet

- Provide comprehensive reports, RH correction, wheel change advice, A% reports, cumulative long-term critical data like long term CV, process capability reports.

Stretch 1500

Compact Table Top Electronic Lea Tester

- Compact Table Top Model – Small Footprint

- Electrically Operated

- Auto return after Lea breakage

- Computerised operator interface for ease of use

- Perfectly Compatible with Cascade System

- Higher Accuracy

- Sleek Model

Cascade

CasLNX software for wrapping

- Cascade – CasLNX software ubuntu OS

- Interface to our balances through Ethernet

- Interface to stretch 1500 / Ethernet

- Provide comprehensive reports, RH correction, wheel change advice, A% reports, cumulative long-term critical data like long term CV, process capability reports.

CASCADE CasLNX – Technical Specifications

| Fibre | Cotton, Synthetic, Worsted Yarn | |

| Material | Sliver, Roving, Yarn | |

| Count Unit | Ne, Tex, Dtex, Ktex, Denier, NM, Nf | |

| Strength Unit | Lbs | |

| Tests | Department | Results |

| Regular Wrapping | All Departments | Count, Count CV%, RH Correction, Min & Max Range, Q95 Limits |

| Draw Frame, Ring Frame | Wheel Change Advice, A% Reports | |

| Ring Frame | Strength, Strength CV%, RH & Count Correction, CSP, CCSP Min & Max Range for Strength, Coefficient of Correlation between count & Strength | |

| Lap to Lap CV% | Blowroom | Lap Weight, Lap – Lap CV% |

| Waste Extraction | Comber | M/c & Delivery-wise Waste %, Deviation, Range, CV% |

| Stretch Test | Speed Frame | Speed Frame Full / Empty Bobbin Front & Back row Average & CV%, Overall Average & CV% |

| Within–Between Bobbin (Count) | Speed Frame, Ring Frame | Within Bobbin CV%, Between Bobbin CV%, Overall CV%, F-Ratio, Mean Sum of Squares |

| Within–Between Bobbin (Strength) | Ring Frame | Within Bobbin CV%, Between Bobbin CV%, Overall CV%, F-Ratio, Mean Sum of Squares |

| Adhoc Tests (No Storage) | All Departments | Count, Count CV%, Strength, Strength CV%, CSP, CCSP |

| Storage | Unlimited | |

| Reports | Wrapping Register for all departments, Period Reports for all departments, Micro Spinning | |

| Graphs Manual Entry |

X-Bar, CV% for Individual tests & Periodic tests | |

| Electronic Balance | Accuracy / Range / Interface | Applied 0.001 g 220 g Ethernet |

| Electronic Lea Strength Tester | Type Mounting Interface |

Electrical with auto return Compact Table Top 0 – 1550 lbs / Ethernet |